Multi-purpose high temperature thermocouple assembly developed for continuous use

to 1600 °C (3000 °F) in both oxidizing or reducing atmospheres-pressures to 70 Kg/cm²

(1000 psi).

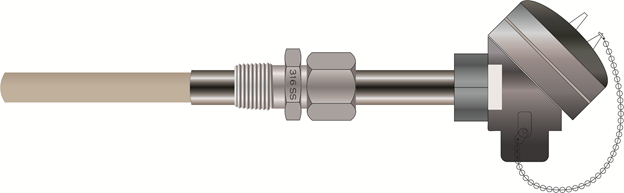

High Temperature Section:

Diameter = 12.7 mm (0.5 in)

Lengths = 76.3 to 433 mm (3 to 17 in)

Support Section "A":

Diameter = 15.9 mm (0.625 in)

Lengths = 102 to 1525 mm (4 to 60 in)

Total Length "L":

178 to 1960mm (7 to 77 in)

Industrial thermocouples may be used for temperatures above the Chromel / Alumel

range in environments that either destroy or render Platinum -Rhodium thermocouples

ineffective due to drift or ageing affects. The refractory Tungsten 5% Rhenium /

Tungsten 26% Rhenium element is protected against contamination or oxidation thru

the unique double insulation-double wall construction that selectively eliminates

all but the beneficial diffusion of Hydrogen. Internal thermocouple junction reliability

is maintained thru a new (patent pending) wire wrap / welding procedure to eliminate

the problems associated with thermal cycling welded junctions on refractory wires.

This sensor combines the stability and sensitivity (4.4 microvolts per °C) of the

new refractory thermocouple combinations with the atmospheric resistance and strength

of cermet’s.

APPLICATION

Gas generator temperature indication and control

Metal annealing, hardening and deoxidizing furnaces

Calcining and glazing Kiln temperature survey and control

Ceramic firing systems

Diffusion furnaces

Commercial 816 to 1600 °C (1500 to 3000 °F) ovens

Liquid steady state metal temperature surveys in Aluminum, Tin, Copper, Copper-Silver

alloys, Lithium

Long term temperature indication for baths with acid salts and corrosive acids (Cyanide

salts and molten borax excluded)

Sulfur Recovery Unit, refractory protection

INSTALLATION

Compression fitting (½" NPT) with metal ferrule supplied with each sensor for immersion

control and pressure tight mounting to any pre-drilled and tapped chamber wall.

Insert threaded end and wrench tighten using hex head adjacent to threads. Insert

thermocouple thru hex head cap to desired immersion depth. Tighten cap ¼ turn beyond

finger tightness.

Note: Thermocouple head is supplied with necessary compression fitting for attachment

to probe. Attach wires, tighten compression fittings on thermocouple head prior

to process installation.

Sulfur Recovery Units.

Coal Gasification Reaction Zones.

Resistance to Hydrogen Sulfide or Sulfur Dioxide.

Eliminated Toxic Gas Leakage.